Cutting-edge Methods for Transformer Oil Purification and Improved Performance

Cutting-edge Methods for Transformer Oil Purification and Improved Performance

Blog Article

Transform Waste Into Worth With Advanced Transformer Oil Recycling

The makeover of waste right into value offers an essential opportunity within the electrical industry, particularly via the lens of advanced transformer oil recycling. By employing cutting edge innovations, such as vacuum cleaner distillation and purification systems, organizations can recuperate important sources from used transformer oil while reducing environmental risks. This practice not just enhances operational efficiency yet additionally straightens with expanding sustainability needs. As industries progressively focus on eco-friendly efforts, the ramifications of these sophisticated recycling techniques warrant closer exam to comprehend their complete possibility and effect on the marketplace.

Understanding Transformer Oil

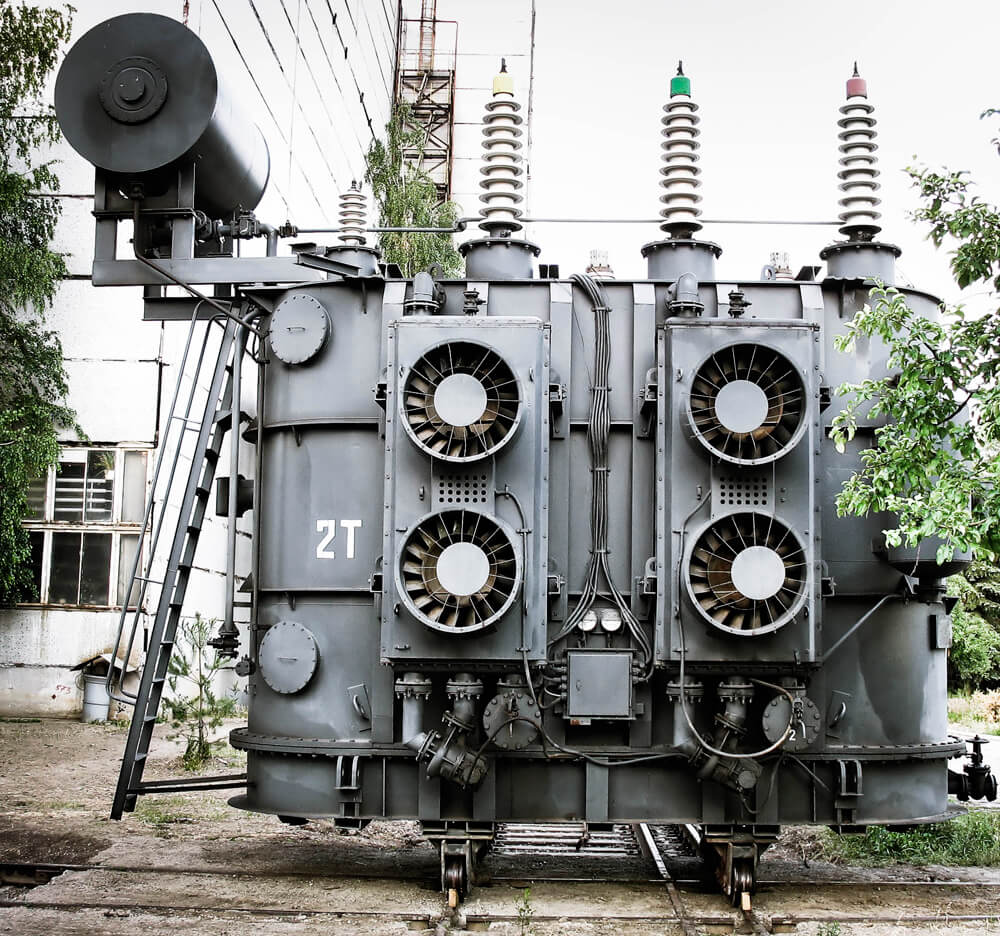

Transformer oil is a customized insulating and cooling down liquid utilized in electric transformers to enhance operational performance and dependability. This oil plays a critical function in preventing electrical discharges and keeping the essential thermal balance within the transformer - Virgin Transformer Oil. It serves to insulate the conductive components, making sure that energy is properly moved while reducing the risk of brief circuits

Typically stemmed from fine-tuned oil, transformer oil is defined by its high dielectric toughness, low viscosity, and a durable chemical stability that permits it to stand up to raised temperatures. The oil's capability to dissipate warmth produced throughout operation is crucial; as transformers convert electric power, they create heat that has to be efficiently managed to prevent tools failing.

Moreover, transformer oil is developed to resist oxidation and destruction, which can lead to the development of sludge and various other dangerous by-products. Routine tracking of oil top quality is crucial, as contaminants can jeopardize its shielding homes and overall performance. Recognizing the composition and functionality of transformer oil is essential for upkeep practices, making sure the longevity and operational stability of transformers in different applications throughout the power industry.

Value of Recycling

Why is reusing transformer oil crucial for both ecological sustainability and financial efficiency? The incorrect disposal of transformer oil can lead to serious ecological risks, consisting of dirt and water contamination.

From an economic point of view, reusing transformer oil offers considerable price savings for companies. The procedure permits companies to reclaim a high-grade item that can be reused in various applications, lowering the need for buying brand-new oil. This not only decreases functional prices yet also reduces garbage disposal costs related to dangerous materials. Reusing sustains the round economic climate by transforming waste right into beneficial resources, therefore fostering lasting practices within the industry (Transformer Oil Recycling).

Advanced Recycling Technologies

As the demand for sustainable techniques in the energy market grows, advanced reusing innovations have actually emerged as an important option for processing used transformer oil. These innovations incorporate a series of ingenious methods created to successfully redeem useful resources while decreasing ecological effect.

One popular method is vacuum distillation, which divides oil components at lower temperature levels, maintaining the quality of the base oil while removing pollutants. This approach enhances the recovery rate and makes certain that the recycled oil meets market criteria. An additional significant improvement is the usage of adsorption and filtering systems, which use specialized products to catch pollutants and bring back the oil's homes efficiently.

Additionally, the integration of chemical treatments, such as neutralization and decolorization, plays a vital role in refining transformer oil. These processes eliminate acids, sludge, and discoloration, leading to top quality recycled oil that can be reused in various applications.

Economic and Environmental Conveniences

The environmental and financial advantages of transformer oil recycling are significant, presenting a dual advantage for both sector stakeholders and environmental preservation. By recycling used transformer oil, firms can considerably lower functional costs related to buying brand-new oil, therefore improving their bottom line. This process not only minimizes waste disposal costs but also permits the recovery of valuable materials, generating additional earnings streams.

From an environmental perspective, recycling transformer oil adds to a decrease in contamination and source depletion (Virgin Transformer Oil). Correct recycling processes minimize the threat of unsafe spills and soil contamination, securing neighborhood ecological communities and advertising biodiversity. Furthermore, repurposing transformer oil decreases the demand for virgin oil extraction, which usually entails eco destructive practices such as boring and refining.

In addition, embracing advanced reusing innovations enhances conformity with strict environmental policies, thus securing firms from prospective responsibilities and fines. The favorable influence on corporate social obligation campaigns can boost a business's credibility, fostering better trust and loyalty among stakeholders and customers. In significance, the financial and environmental advantages of transformer oil reusing emphasize its importance as a sustainable practice in the energy industry.

Future of Transformer Oil Recycling

Structure on the significant financial and environmental advantages highlighted, the future of transformer oil recycling shows up encouraging, driven by technical innovations and enhancing regulative stress. Innovations in recycling innovations, such as improved purification systems and chemical handling techniques, are expected to improve the efficiency and performance of oil recovery processes. These improvements not just reduce waste however additionally optimize the high quality of recycled oil, making it better for reuse in various applications.

In addition, as federal governments and regulatory bodies globally execute stricter environmental standards, the demand for sustainable techniques will climb. This change will certainly compel markets to adopt transformer oil reusing as an important element of their operational techniques. Business that focus on environment-friendly practices are most likely to acquire an one-upmanship, interesting eco mindful consumers and stakeholders.

Final Thought

The recycling of transformer oil with advanced modern technologies not just saves important resources yet additionally considerably reduces ecological dangers related to garbage disposal. By taking on innovative techniques such as vacuum cleaner distillation and filtering, the electrical sector can enhance sustainability while website here simultaneously producing and reducing functional expenses earnings. As the concentrate on eco-friendly practices magnifies, the future of transformer oil recycling shows up promising, placing business to flourish in a progressively open market that prioritizes sustainability and environmental duty.

Transformer oil is a customized cooling down and shielding liquid utilized in electrical transformers to improve operational effectiveness and dependability. Recognizing the structure and capability of transformer oil is important for upkeep techniques, making sure the long life and functional stability of transformers in different applications throughout the power industry.

One famous method is vacuum cleaner purification, which separates oil elements at reduced temperatures, protecting the website here top quality of the base oil while removing contaminants. By reprocessing used transformer oil, firms can substantially minimize operational prices associated with buying brand-new oil, hence boosting their bottom line. Repurposing transformer oil decreases the demand for virgin oil extraction, which typically includes environmentally check this site out damaging techniques such as exploration and refining.

Report this page